Driving the Circular Economy through Material Innovation: Huntsman Builds a New Ecosystem for Sustainable Development

Huntsman Corporation is a multinational publicly traded company specializing in the production and sale of differentiated and specialty chemicals. In 2024, the company achieved approximately $6 billion in revenue. Huntsman has developed thousands of chemical products, which are distributed to manufacturers worldwide, serving a diverse range of consumer and industrial end markets.

At CHINAPLAS 2025 in Shenzhen, Huntsman presented under the theme "Innovating Together for a Sustainable Future", showcasing a cutting-edge product portfolio and industry solutions that exemplify how technology can drive sustainable innovation. As a pioneer in thermoplastic polyurethane (TPU) materials technology, Huntsman has built an extensive sustainable ecosystem encompassing R&D, production, application, and recycling.

Customer-Centric Approach Driving TPU Process Innovation and Sustainable Development

Huntsman has long been committed to sustainability, as reflected in its annual sustainability reports, which discloses the company's achievements in emission reduction, resource circularity, and green innovation. Maintaining close collaboration with customers, Huntsman actively participates in every stage—from process improvement to product design—to ensure that its solutions are practical and effectively implemented.

In advancing its sustainability strategy, Huntsman places safety at the core of its operations, encompassing personnel safety, product safety, and production safety. Within the manufacturing process, the company focuses on enhancing efficiency through sustainable technological solutions. In the realm of sustainable products, Huntsman has developed three key customer-oriented solution areas:

-

Bio-Based Materials: Developing products derived from renewable resources to reduce reliance on fossil fuels.

-

Circular Economy: Offering recyclable and reusable material solutions to support a closed-loop lifecycle for resources.

-

Biomass Balance (BMB): Using biotechnology to optimize material structures, achieving a balance between environmental friendliness and high performance.

Matthew Canoy, Global Marketing Director for Huntsman's Polyurethane Elastomers Division, emphasized Huntsman's strong commitment to customer collaboration. While meeting stringent performance requirements, the company aligns closely with customers' sustainability strategies, offering critical support for green certifications and enhancing the market competitiveness of end products.

Tackling Key Challenges in the TPU Circular Economy: Achieving the Balance Between Performance and Sustainability

Due to its unique chemical structure, physical properties, and environmental friendliness, TPU has inherent advantages in the circular economy. However, in practical application, the recycling of TPU products relies on collaboration across the entire value chain, and the complexity of the materials involved presents significant challenges for achieving effective circularity.

Take footwear as an example. The lifecycle—from TPU raw material suppliers, outsole and upper fabric producers, and shoe manufacturers, to brand owners, retailers, and end-of-life recycling systems—requires a unified framework of technical standards and shared value mechanisms. Compounding the challenge, post-consumer shoes are composed of diverse materials (TPU, EVA, rubber, adhesives, etc.), making separation and recycling technically difficult.

Matthew Canoy highlighted that circular solutions must be tailored to the specific characteristics of different materials:

-

Physical Recycling Innovation: Thermoplastic materials like TPU can be efficiently recycled through melt reprocessing. In Europe, for instance, TPU is widely reused in footwear via physical recycling systems.

-

Chemical Recycling Breakthroughs: For complex composites (e.g., shoes made with multiple bonded materials), chemical decomposition technologies are being developed to regenerate otherwise non-recyclable components.

To this end, Huntsman has been working closely with partners to implement such strategies. In response to growing consumer demand for both eco-friendliness and cost-effectiveness, the company has introduced several innovative material solutions, including the SMARTLITE® O LTPU system and the AVALON® GECKO TPU series.

The SMARTLITE® O LTPU system is a liquid thermoplastic polyurethane (LTPU) developed by Huntsman specifically for footwear midsoles. This system delivers outstanding hydrolysis resistance along with superior cushioning comfort and rebound performance.

Compared to traditional foamed TPU systems—which require complex processes like supercritical foaming and steam molding—SMARTLITE® O LTPU is significantly more user-friendly, utilizing a single-step injection process that greatly reduces water usage, energy consumption, waste, and carbon emissions. Most importantly, waste generated during both industrial production and post-consumer use can be recycled, contributing to a more sustainable product lifecycle.

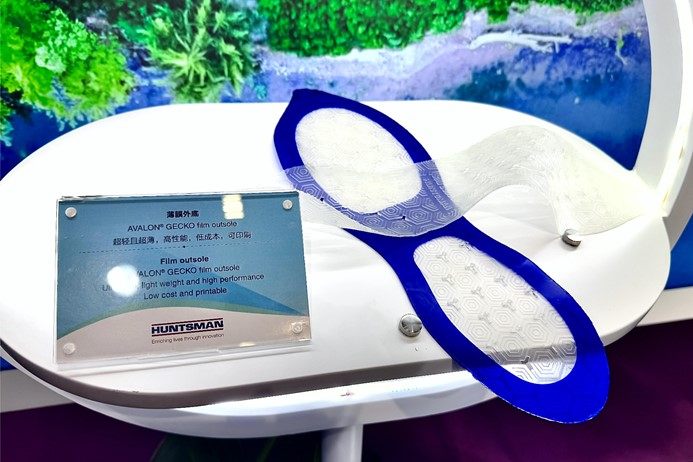

The AVALON® GECKO TPU series represents a breakthrough innovation by Huntsman for outsole applications, tailored for high-performance footwear. This product line includes extrusion-grade materials ideal for creating ultra-thin outsoles, as well as foamed materials that deliver exceptionally low density, superior softness, and a distinctive tactile feel.

Unlike traditional TPUs, which are often limited in slip resistance, GECKO materials rival rubber in anti-slip performance. Outsoles made with GECKO are up to 50% lighter and thinner than conventional alternatives. Additionally, when paired with other TPU-based midsole materials, outsoles made from the GECKO series can be bonded without the need for adhesives, enabling seamless integration and facilitating mechanical recycling with minimal impact on material performance.

Leveraging the dual demand from downstream customers for high performance and low carbon, Huntsman collaborates with customers to co-create innovative TPU solutions. Together, they are building a closed-loop system that spans product design and application to end-of-life recycling and regenerative manufacturing. This market-driven technological upgrade, reinforced by a recycling network that feeds back into raw material supply, forms a circular model that strategically aligns environmental benefits with commercial value.

Unlocking the Low-Carbon Economy with TPU: Empowering Industries Across the Board

Matthew Canoy emphasized that realizing a true circular economy requires coordinated effort across the entire value chain. Beyond advancements in footwear, Huntsman's TPU materials have made significant inroads into core sectors such as automotive, construction, cable systems, and industrial applications. By enhancing product performance and offering sustainable alternatives, Huntsman is enabling a broad spectrum of industries to move decisively toward a more sustainable future.

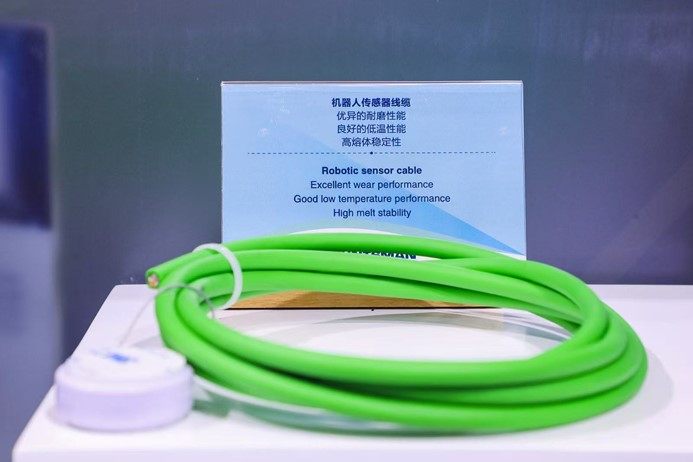

With the rapid surge in demand for new energy vehicles, charging infrastructure, and smart devices, cable materials are now required to meet higher standards in flame retardancy, weather resistance, and environmental performance. Huntsman's TPU cable materials, featuring halogen-free flame retardancy, oil and corrosion resistance, and recyclability, are increasingly replacing traditional PVC and rubber. These materials have become the preferred choice for high-voltage vehicle wiring, EV charging cables, and medical device cords.

In the industrial sector, Huntsman delivers tailored TPU solutions to meet diverse application demands. For heavy-duty transport, its ultra-abrasion-resistant TPU conveyor belts are designed to handle sharp and heavy materials such as ore and metal, ensuring exceptional durability. In food processing environments, Huntsman has developed food-grade TPU conveyor belts that meet stringent hygiene standards and offer superior resistance to contamination. These innovations represent a dual breakthrough, combining environmental sustainability with high functional performance to support safer, more efficient industrial operations.

Forward-Looking Strategy: Shaping the Future of Material Innovation

In response to emerging sectors such as 3D-printed footwear, Huntsman is pursuing a dual-track approach that combines technological preparedness with continuous market monitoring. Matthew Canoy noted that while the 3D-printed footwear market has yet to experience a major breakthrough, the company has already developed TPU filaments specifically for 3D printing and is prepared to respond swiftly as industrial adoption accelerates.

Guided by a principle of pragmatic innovation, Huntsman remains committed to focusing on scalable, cutting-edge technologies, reinforcing its leadership in the field of sustainable materials.

资料下载:

资料下载:

欢迎点击加入鞋材弹性体通讯录,点击下方标签可以查看通讯录名录